News

WorldAutoSteel Update – Summer 2024

Welcome to the summer edition of WorldAutoSteel Update, a periodic summary of our recent initiatives. These bulletins spotlight timely news and information about how steel is helping to drive the future of sustainable mobility. Sign up here to make sure you don’t miss future issues! Ternium & WorldAutoSteel Announce Winners of Steel E-Motive Student Competition […]

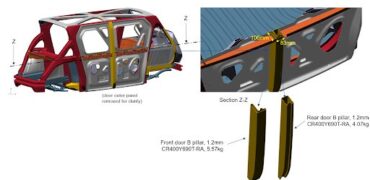

Steel E-Motive Demonstrates Benefits Of Part Integration

High-volume automotive body structures using Advanced High-Strength Steel (AHSS) grades offer the potential for low cost and weight, high strength performance, and competitive life-cycle and sustainability attributes. Reducing the number of individual parts within an automotive body structure can yield further cost, weight, and sustainability benefits without compromising performance. WorldAutoSteel’s latest engineering demonstrator project, Steel […]

Student Project Showcases Innovation in Interior Design of Mobility-as-a-Service Concept Steel E-Motive

WorldAutoSteel’s Steel E-Motive program showcases autonomous ride-sharing vehicle concepts (known as Mobility-as-a-Service or MAAS). It highlights steel’s strength and durability, with a critical focus on sustainability for reaching net zero emissions targets. While these concepts feature the application of Advanced High-Strength Steels (AHSS) for safety and comfort, the specific interior design was not part of […]

Part Consolidation in the Battery Structure = Cost Mitigation

Part consolidation in the battery structure provides cost savings in material requirements and reduced investment in required tooling. Another benefit of assembly simplification is improved quality. Fewer components mean fewer sealing surfaces, resulting in less rework in the assembly process, where every battery tray is leak-tested. Read more in this article on our AHSS Insights […]

How Steel Properties Influence the Roll Forming Process

Optimizing the use of roll forming requires understanding how the sheet metal behaves through the process. Making a bend in a roll-formed part occurs only when forming forces exceed the metal’s yield strength, causing plastic deformation to occur. Higher-strength sheet metals increase forming force requirements, leading to the need to have larger shaft diameters in […]

WorldAutoSteel Update – Spring 2024

We welcome you to the inaugural edition of WorldAutoSteel Update – a periodic summary of our recent initiatives. These bulletins are designed to spotlight timely news and information about how steel is helping to drive the future of sustainable mobility. WorldAutoSteel is the automotive group of the World Steel Association. Our mission is to advance […]

Resistance Spot Welding AHSS to Magnesium

There is an increased need to join magnesium alloys to high-strength steels to create multi-material lightweight body structures for fuel-efficient vehicles. These lightweight vehicle structures are essential for improving the fuel economy of internal combustion engine automobiles and increasing the driving range of electric vehicles by offsetting the weight of power systems. We continue to […]

Student Engineers to Adapt SEM2 from People Mover to Commercial Delivery Vehicle

WorldAutoSteel advances steel’s advantages in the automotive and future mobility industries. We’re committed to engaging with future engineers at post-secondary education organizations around the globe. Our most recent engineering project, Steel E-Motive, was created to help the industry meet the challenges of future mobility and Level-5 autonomous vehicles and eventually reach net zero emissions targets. […]

Meeting the Engineering Challenges of Autonomous Vehicles: The Steel E-Motive Student Engagement

For the Steel E-Motive project, we engaged Ricardo plc to collaborate with our technical directors to develop a Level 5 Autonomous Vehicle. The project uncovered a few challenges that were solved by student engineering teams through Senior Capstone Projects. The Side Door and Door Hinges project was created at Michigan Technological University by the students […]